Production of castings is a complex matter, not only about melting and casting itself. After the customer’s request, a manufacturability study is prepared, where we evaluate the suitability of the casting for the production of our technology. This is followed by the layout of the castings on the model device, calculation of the inlet system and creation of its 3D model. A simulation of casting and solidification of a casting is performed in the Magma program, which uses the finite element method to display events in the inlet system. After the results come in, the inlet system is optimized. Using 3D data of the inlet system, a model device for automatic forming is manufactured. It is then possible to cast the first samples.

0.1 to 3.0 kg

Max 300 x 400 mm

From 1 000 pieces yearly

Nodular Cast Iron

Production of castings in the preparation process

The process of production preparation and the production of model equipment itself is a relatively expensive matter. For this reason, it is suitable for medium to large series of castings, between thousands to hundreds of thousands of pieces.

The charge, consisting of selected crude iron, steel scrap and the actual gate, is melted in two induction medium-frequency crucible furnaces with a volume of 3 t per crucible. One furnace melts, the other maintains the temperature of the metal and gradually pours it according to the requirements of the molding plant. At the end of the melting, the melt is alloyed according to the laboratory’s prescription and the result of the chemical composition and the melt is heated to the required temperature.

Cast iron modification process

The metal is poured from the furnace into transport modification ladles with a volume of 350 kg. Using a handling technique, the ladle is placed in a modification device, where an automatic casting modification process is performed. According to the results of temperature measurements, sulfur content and set utilization, the exact amount of modification filled profile is introduced into the melt, where modification occurs during turbulent reactions. After the modification, the slag is removed and the metal is poured into a casting ladle with a volume of 450 kg.

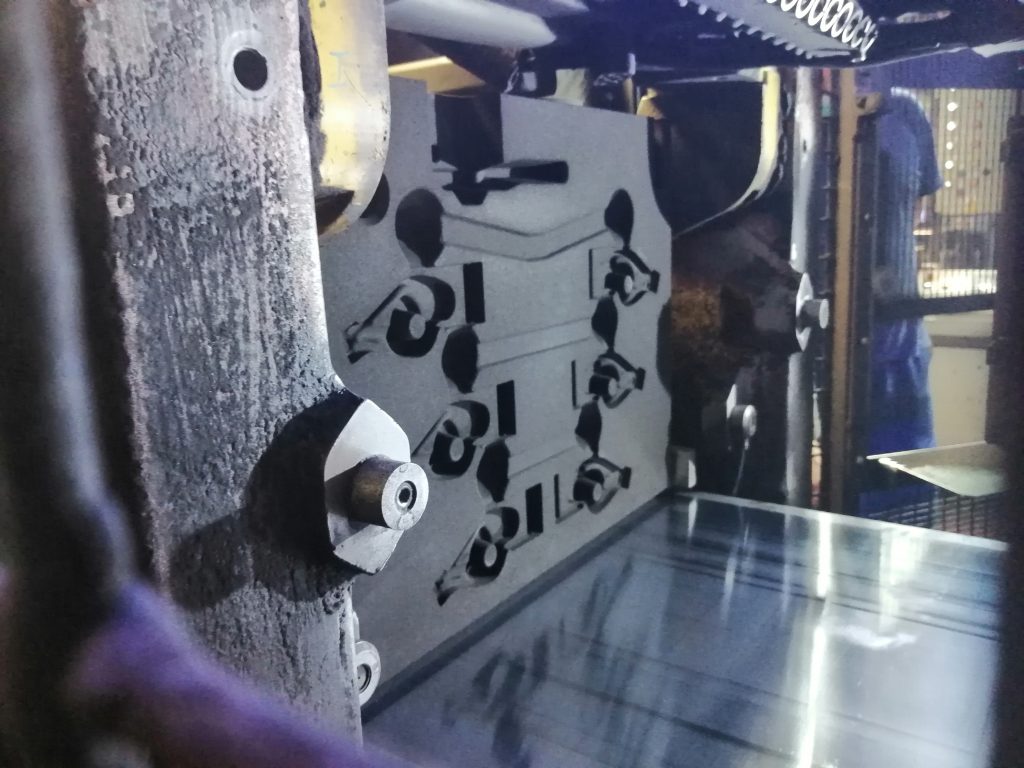

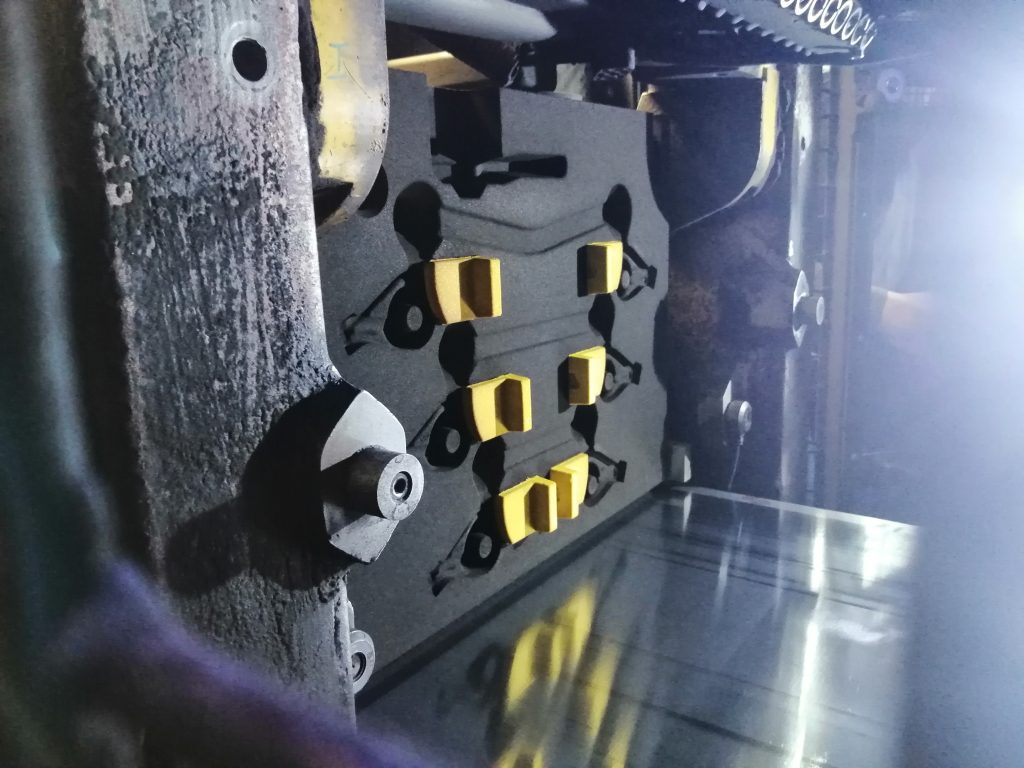

Metal forming

The metal is cast on an automatic casting machine with inoculation into a metal stream. Forming takes place on Disamatic machines with a vertical dividing plane with a frame size of 500 x 400 mm. This method of molding is characterized by high productivity. Cores made by hot-box methods with a binder of the type novolak Thermoplastic, a necessary raw material used in the production of sealants, adhesives, varnishes and resol, are automatically inserted into the molds.

Smaller size of the molding frame has the disadvantage of a smaller number of castings in the frame, which is balanced by higher accuracy of castings and better quality surfaces, because there is less ferrostatic pressure in the inlet system with a lower height.

Foundry specialization

The foundry specializes in a range of light castings from 0.1 to 3.0 kg. Cast iron with spheroidal graphite (ductile iron) is cast mainly, because spheroidal graphite cast iron is a specific and demanding material from the production point of view and quality compliance, there are not many foundries on the market that specialize in the production of spheroidal graphite cast iron castings. Most foundries offer castings only from cast iron with flake graphite (gray cast iron) which only has a marginal representation in Seco Industries, s.r.o. also due to limited production capacities.

Quality control

Along with the castings, various samples are regularly cast and taken. From them, the chemical composition, mechanical properties, quality control of the modification of each modification batch (nodularity value) are evaluated. The hardness of the sample casting and its structure is checked on the metallographic cut.

The final stage of production of castings

After casting, the castings solidify and cool together with the inlet system on the conveyor, from which they fall onto the hammering grate after approx. 30 minutes. Inlet systems with castings are discharged from molds on the hammering grate. After treatment, the molding sand is used again for the production of molds. Inlet systems with castings are shut down for about 24 hours until they cool down completely.

They are then weighed into blasters and the layer of sand, stuck on their surface, is removed. The castings are separated from the inlet system by cutting or hitting. Furthermore, the castings are ground by hand or on grinding machines. After grinding, the castings are blasted again and transported to the final inspection, where there is a 100% inspection of the surface for various foundry defects. Compliant castings are packed and taken to a warehouse for dispatch.