What is milling?

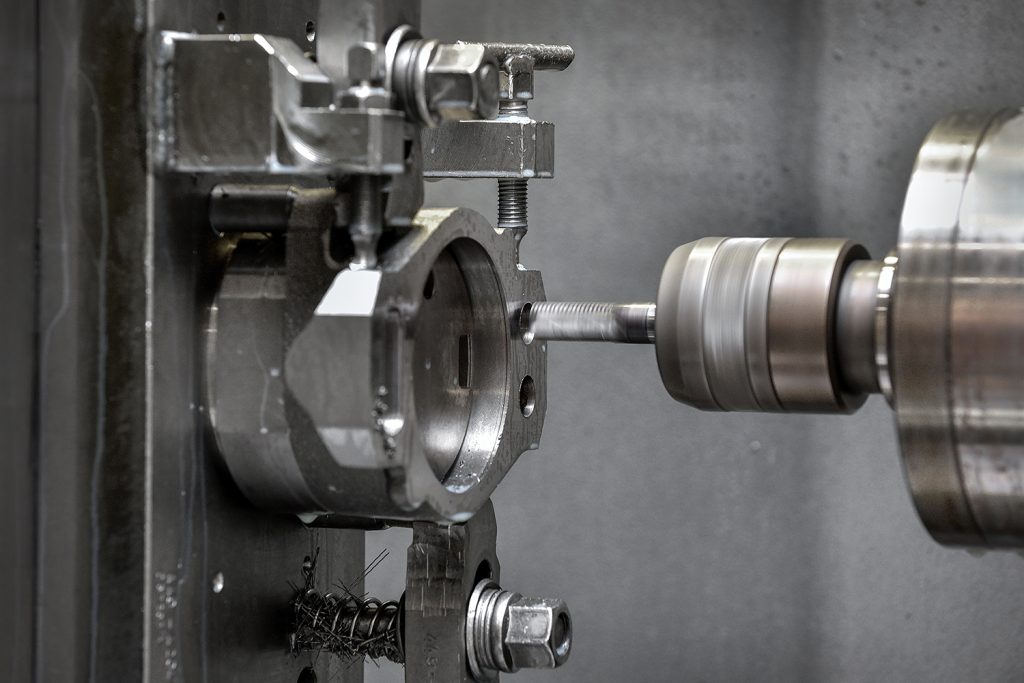

By milling, planar surfaces, shaped surfaces perpendicular to one (eg horizontal) plane, surfaces of a rotating gear wheel (on a hobbing machine), or other workpiece surfaces are machined on a milling machine with a rotating milling machine.

The main, rotary movement in all types of milling is performed by a tool. This movement is given by the cutting speed. The secondary feed movement is usually rectilinear and is performed by the workpiece. For circular and planetary milling, it can also be rotary and can be performed by a workpiece or a tool.

Milling can be divided according to the type of cutter feed into the following variants:

Consecutive

The cutter rotates in the sense of shift, the teeth begin to cut the chip in the place with the greatest thickness, the milling is impact based, the tooth blades do not slide on the material, thus creating less heat making the cutter heats up less. It is possible to select a higher cutting speed and larger feeds, the workpiece is pressed against the support surface of the chuck by the cutting force. This variant is suitable for milling thin-walled workpieces, with a large depth of cut, the milling machine must have as little play as possible in the feeds and guide surfaces.

Inconsistent

The cutter rotates against the direction of shift, the chip is formed from the smallest zero thickness at the beginning of the cut. The work of the cutter is without impact, i.e., more accurate in the results, therefore this alternative is suitable for forgings and castings that have a hard surface layer.