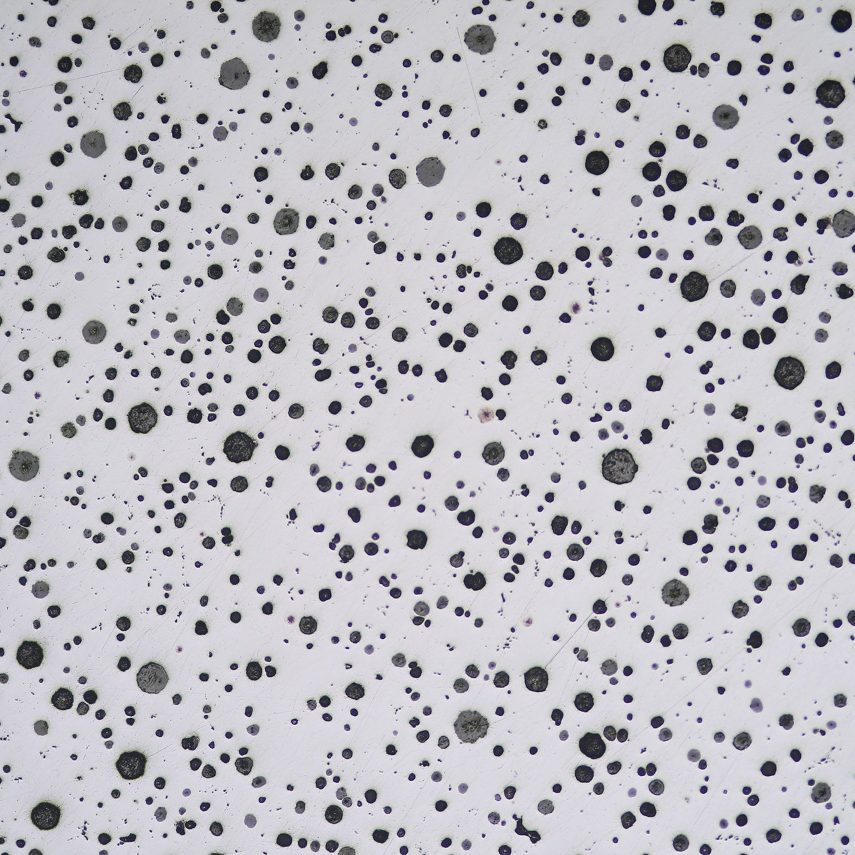

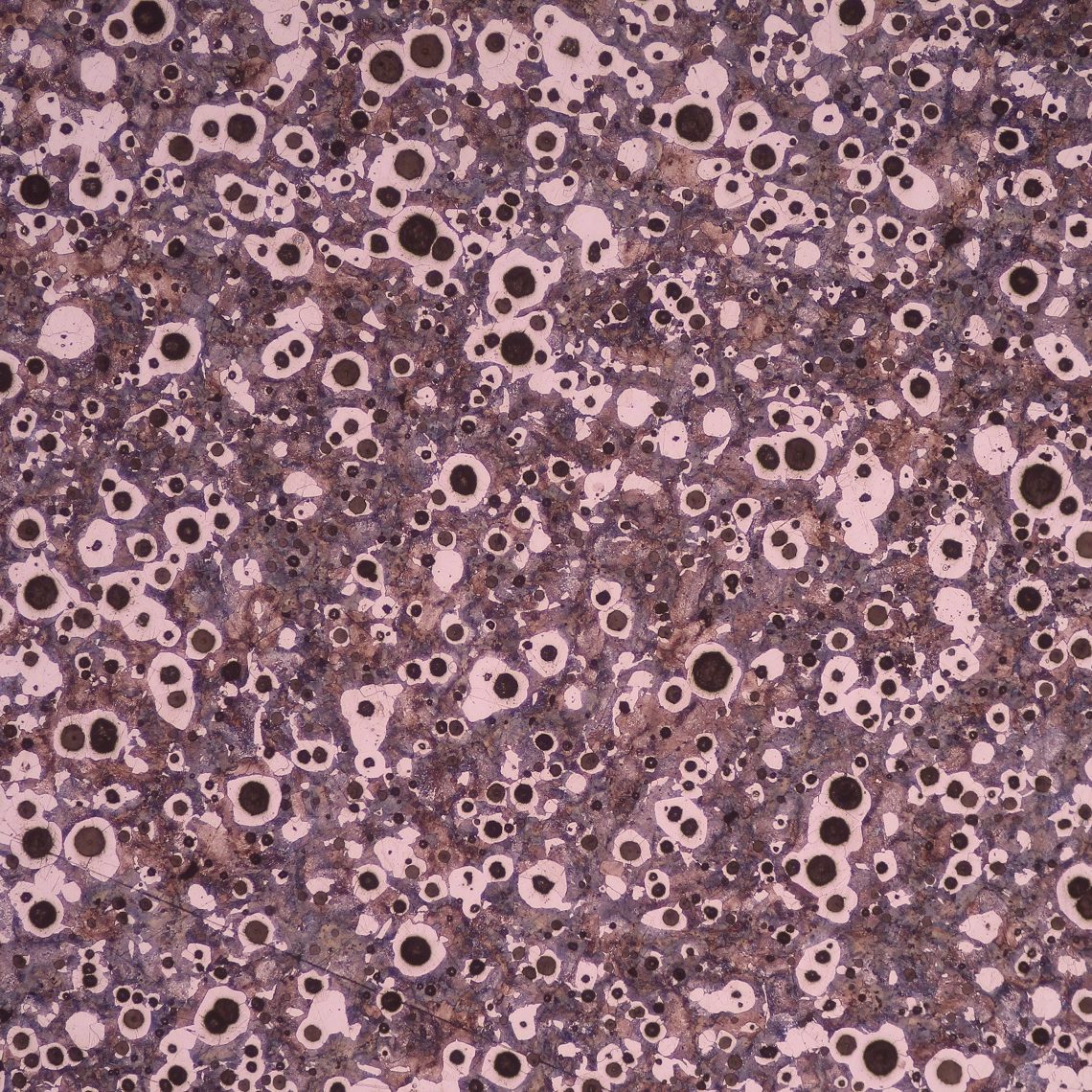

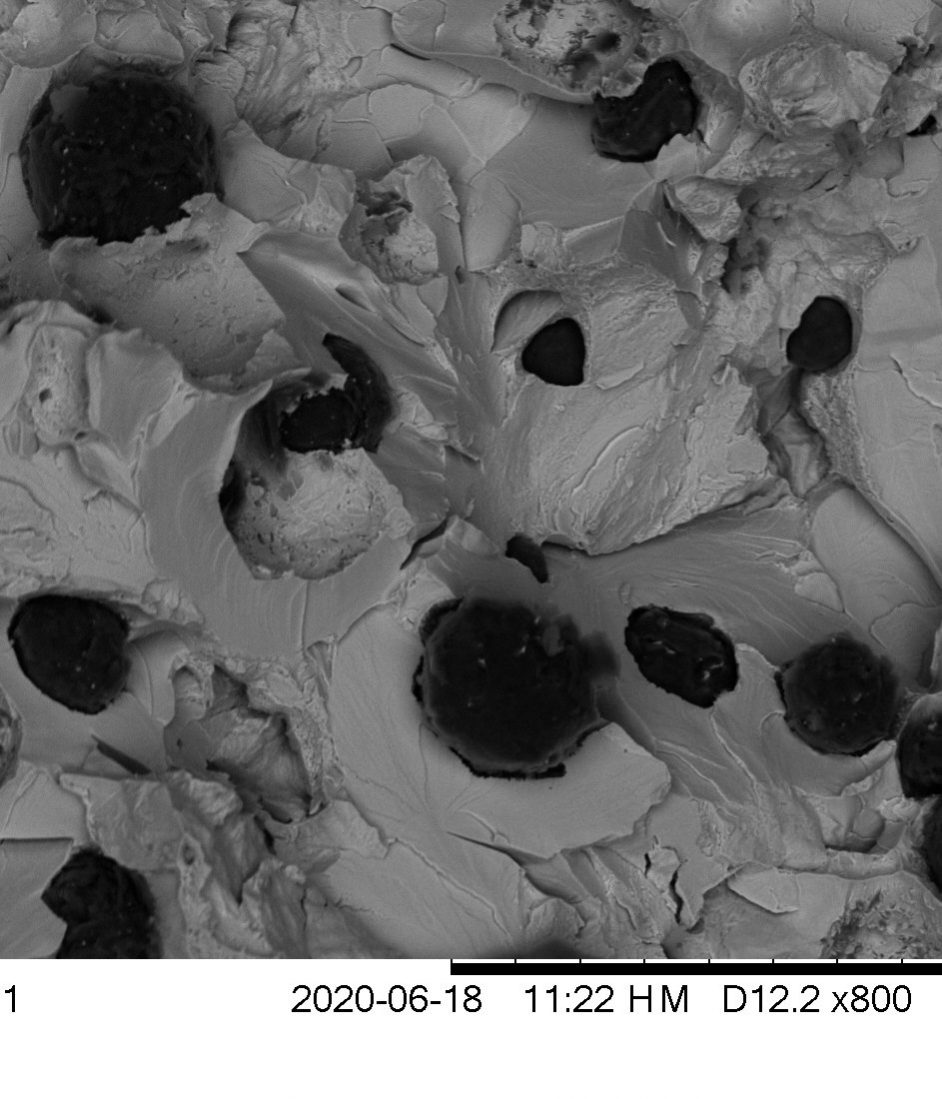

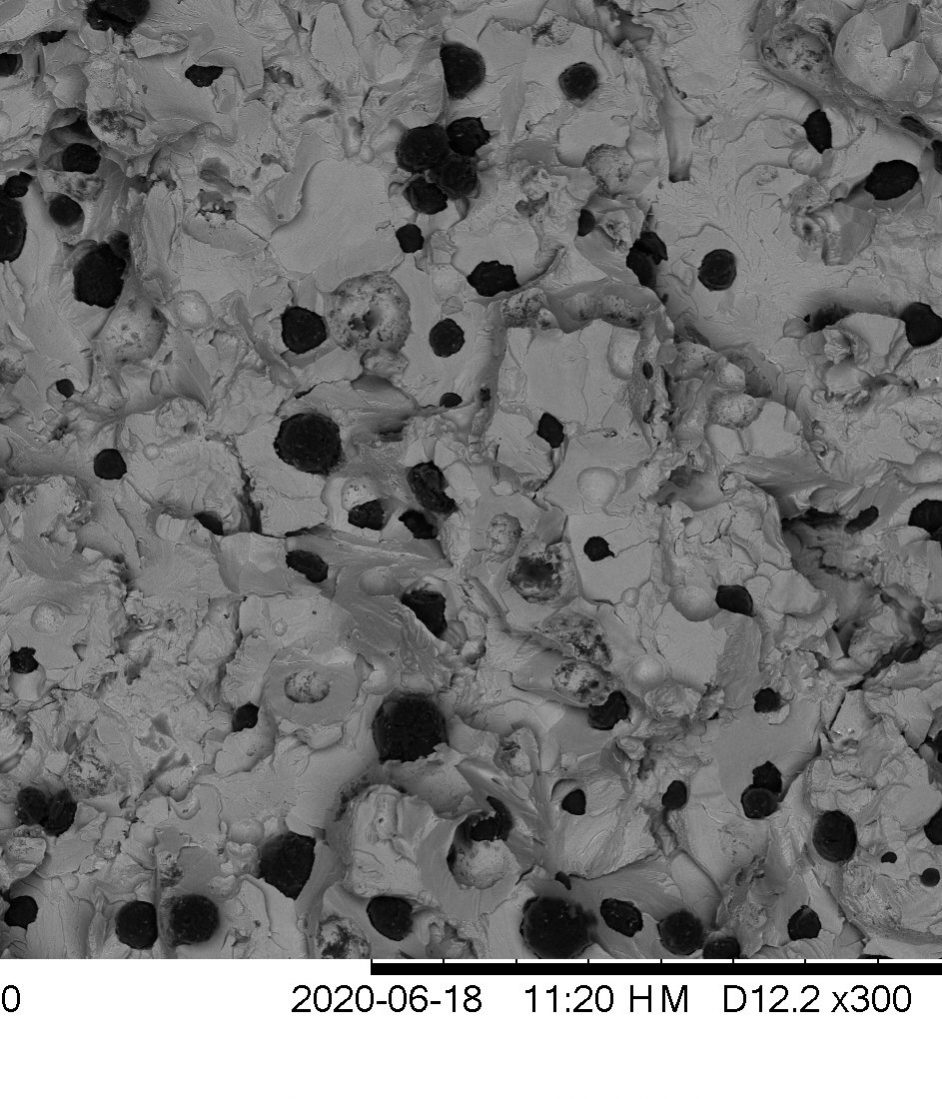

Ductile iron is one of the oldest and most widely used materials in the industry. It is an iron-carbon alloy, where carbon is present in the form of regular spherical grains. It has many properties that make it such a widely used material, such as strength, hardness, wear resistance, thermal conductivity, but it is also important to mention its ability for further heat treatment to achieve the final useful properties and good machinability.

Ductile iron and its advantages

In addition to the properties mentioned above, ductile iron also has several other advantages over other materials. For example, it has a lower price than steel, lower thermal expansion, and is corrosion-resistant. Another advantage is heat resistance – it can withstand very high temperatures, making it suitable for boilers, high-pressure cylinders, or machining tools. These properties make ductile iron an ideal material for many industrial applications.

What is ductile iron used for?

Ductile iron is used to manufacture many different products, whether it is machine components, castings, pipes, valves, engine covers, and much more. Why? Its wide range of applications is due to its ability to be cast into various complex shapes while maintaining strength and durability. Thanks to this, ductile iron is a sought-after material in all industries, especially in the automotive and railway industries, construction, energy, and agriculture.

Processing of ductile iron at Seco Industries, s.r.o.

In our foundry Seco Industries, s.r.o., the basic metal for the production of ductile iron is melted in a medium-frequency induction electric furnace. The ductile iron is formed by adding magnesium to the basic metal, where the carbon is packed into spherical grains. This modified metal is then poured into sand molds by an automatic pouring device. The high production precision of our ductile iron castings ultimately results in an economic benefit from the cost savings on machining.

Technological and production capabilities of ductile iron at Seco Industries, s.r.o.:

- Weight of castings from 0.10 to 4.0 kg

- Casting accuracy according to ISO 8062-3, DCTG 7, EN 1563

- Ductile iron material according to standards EN-GJS 400-15, EN-GJS 450-10, EN-GJS 500-7, EN-GJS 600-3, EN-GJS 700-2

Related category: Gray cast iron